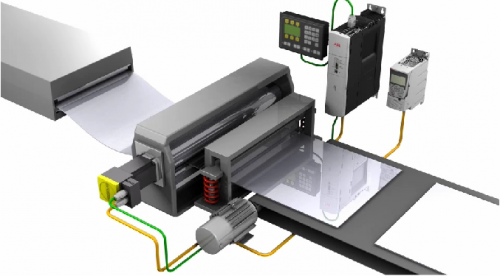

Cut to Length with a Vertical Knife

The product is fed into the cutting area and its length measured from a registration mark with an auxilaiary encoder. The process stops momentariliy when the correct length is achieved and the cut is made - the process then continues. This is the simplest process for cutting or feeding material.

This application also makes use of the motion controller's high speed position latch capability to accurately detect the registration marks on the material.

Special features used:

- Auxiliary encoder for product synchronisation

- High speed position latch to accurately measure product position

Products:

All of Baldor's motion control products can be used to solve this application

Application notes:

The following application notes are relevant to this application:

|

|

AN00122

|

Using flying shears for embossing, rotary knife, sheet feeder and labeling applications

|

|

|

AN00116

|

Understanding how flying shears work for synchronized motion

|

Further application notes are available.